Contact us today on 086 8210557 or

email: info@ecowbs.ie

BHZ

A heating system must rely on the co-operation of its heat generating devices and energy management system.

There is definitely no easier, comfortable and more understandable way of operating a heating system than with

BRUNNER’s Heating Centre (BHZ).

BHZ

The BHZ - Heat Management System consisting of a multi-layered buffer tank, hydraulic box with necessary pumps and connections, and a central control unit including a touch-sensitive panel.

As perfect and simple as possible - there is no better way to ensure a more efficient operation of a complex heating system. The BHZ unit set-up is adaptable to the given requirements and wishes of our customers. Without much effort, it is possible to modify and expand the functionality of all components and connections.

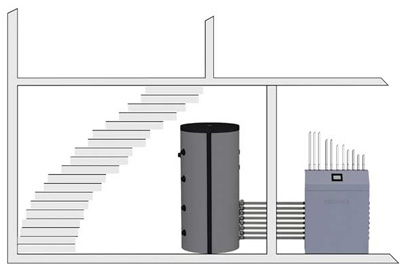

There are two variants :

It is possible to set the storage tank and the Hydraulic box together or to separate them up from each other and build away.

Benefits of BHZ:

• Structure is modular and space saving

• Installation is fast and error-free

• Operating display in the living area mountable

• Foolproof connections

• Upgradeable and expandable

Also, allows space-saving built under a staircase the tank and

in the boiler room there is space for the Hydraulic box and

the system eventually is operated via a display in the

entrance area.

Hot Water System

...in the adjacent hot water tank:

A renovation of the heating system does not mean that the old hot water tank must be replaced.

If it is still functional, then a further use is particularly useful as an additional reserve of drinking

water, if multiple bathrooms are used simultaneously.

...with fresh water module:

Unlike conventional hot water systems, the generously sized plate heat exchanger in the CNF heats the water only when needed to the desired temperature . This is not the heated water for several days, as the norm in hot water systems with large water tanks (150-300 litres) usual. The large plate heat exchanger of the CNF covers draw-off rates up to 25 l/min without temperature fluctuations. A controlled pump controls the flow rate and the temperature. Thus, the amount of water needed is only exactly warmed.

Scalding:

With an adjustable, thermal mixing valve BM between cold and hot water circuit the hot water temperature is limited to

55°C . This has safety reasons : In buffers, which are heated by solar thermal systems, the water in the summer, is often 80°C or more. Then hot water is drawn off via the plate heat exchanger, it can cause burns without a safety device .

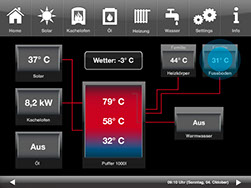

Touch Screen

Thanks to a touch sensitive colour display all settings can be made and edited very easily. The system is available in many different languages using as little technical terminology as possible. Supportive help texts for every individual topic make an operating manual redundant. This way your heating system can easily be controlled and set by basically anyone.

The touch screen is available in black or white glass.

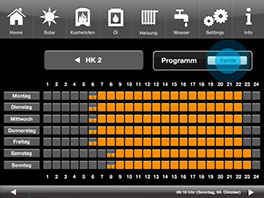

Next to information regarding the selected heating system the heating program can be selected via corresponding button.

Operation

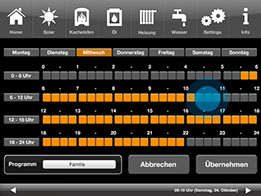

The display has an easy and intuitive user interface and can be operated by literally everyone. Editing settings for your heating program is no longer a challenge. Simply select the desired heating circuit and the menu appears.

A timetable displays heating - standby times. The time slots marked in grey show reduced heating periods.

The heating plan can be customised to your personal needs. The periods highlighted in orange display the active heating sessions.

The new heating program can be saved under its own name. This way you can also save standby times for hot water, circulation and additional heat generators.

Always at your fingertips - the display in your living room or hallway.

The touch display is available in black and white glass. The display or a second display can be built into the flush mounted boxes up to 50m away from the motherboard.

Heat Generators connected to the BHZ have an integrated hot water - amount measurement displaying the current power. Under the button 'buffer' yield can be retrieved.

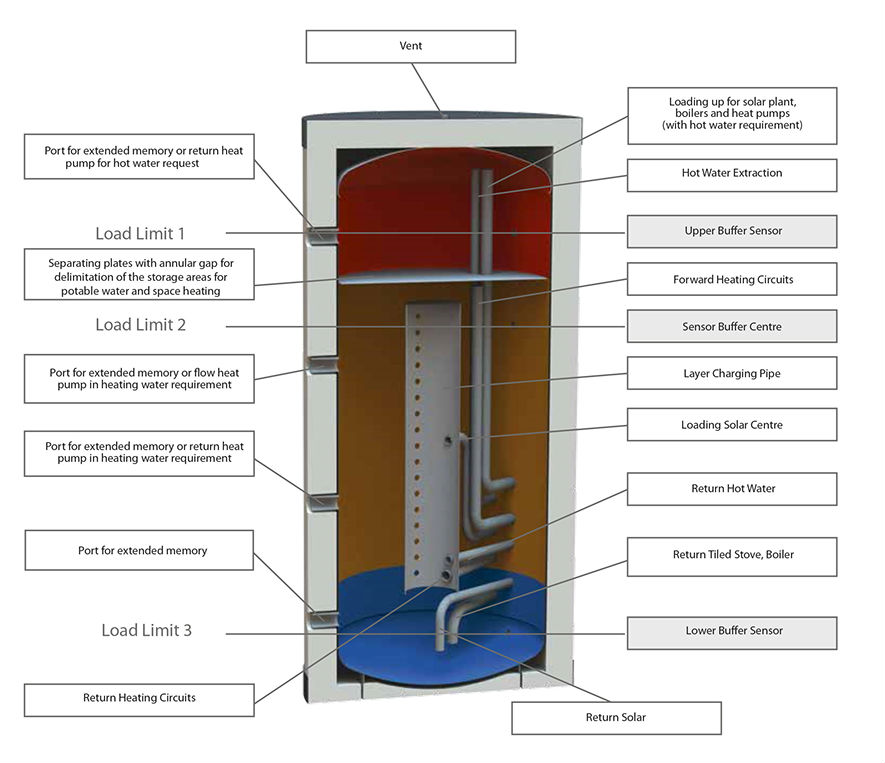

The System Storage (Buffer Tank)

The Buffer Tank by BRUNNER is where all the energy flows are collected, stored and emitted when necessary.

What sound easy isn’t always that easy in practise. Different temperatures and power loads have to be moved. With more than 20 years of experience BRUNNER managed to perfect the thermal layer principle.

The result is a precise thermal layering without allowing the in and outlet velocity to mix up the content.

Set point temperatures and flow velocity are controlled and adjusted in the hydraulic box. Integrated heat plate exchangers ensure heat transportation between separated device areas (solar system, drinking water heat up). This state of the art and elaborated solution optimises stratification and efficiency. Integrated pipe coil exchangers in the buffer destroy the stratification profile (immersion heater principle) and are not offered.

The Right Buffer Size:

750 litres: for heat generators up to 15 kW and small to medium solar systems (absorber surface to 15 m2)

1000 litres: for heat generators up to 20 kW and small to medium solar systems (absorber surface to 25 m2)

1500 litres: for heat generators up to 30 kW and medium to large solar systems (absorber surface up to 25 m2)

2000 litres: for heat generators up to 50 kW and medium to large solar systems (absorber surface up to 25 m2)

The Storage Zones

The heat flows are matched to each other such that three different temperature zones develop in the stratified charge accumulator. The hottest part (190 – 265 litres), on the top is intended solely to heat up domestic water. The second part lies underneath supplying the heating system. The cooler heating water of the return flow is fed into the bottom part. The loading of the storage area is carried taking the eco-hierarchical approach into account considering the particular loading limit.

BHZ

Heating control: Function guarantee

Every house owner who has ever dealt with integrating a new energy source knows exactly how complicated that can be. BRUNNER's Heating Centre consists of fixed connection points in a hydraulic box, which can also be connected to different components. Hence, meeting all requirements for future integration of new energy sources in a technically simple and efficient way.

This is what BRUNNER calls Function / Future Guarantee.

BRUNNER has over 20 years of experience in optimizing buffer tanks, hydraulic and integrated controls for heating systems including regenerative energy source.

Eco Wood Burning Stoves

Kieran Brennan,

Massford, Moneenroe, Castlecomer, Co. Kilkenny.

Mobile: 086 8210557

Email: info@ecowbs.ie

Web: www.ecowbs.ie